What is Fero AI used for?

Fero is used by process engineers, metallurgists, and plant managers to support process decision-making across the full lifecycle of operations. Process engineers use Fero to:

- Understand why process performance changes

- Explore which actions are likely to work before applying them

- Predict unseen issues and use AI recommendations to resolve them faster

Crucially, Fero makes the reasoning behind these decisions visible—showing which variables matter, how they interact, and why certain actions are recommended—so decisions can be explained, reviewed, and trusted.

How the platform works in practice

The Fero Labs Profitable Sustainability Platform is structured around how process decisions are actually made in plants—not how analytics models are typically built. It combines four tightly connected capabilities:

Fero Foundation

Fero Foundation connects historian data and external data sources, and maps process context so information reflects how the process actually runs.

Fero Diagnostics

Fero Diagnostics supports faster root-cause analysis by examining broader sets of process data than is practical manually, while clearly showing the relationships and drivers behind observed behavior, not just statistical outputs.

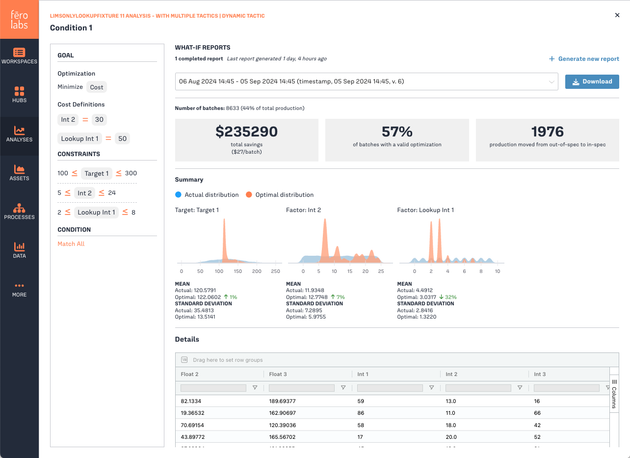

Fero Simulator

Fero Simulator provides a digital twin environment to explore process changes and identify more effective setpoints with transparent cause-and-effect, allowing engineers to see why a change works before applying it.

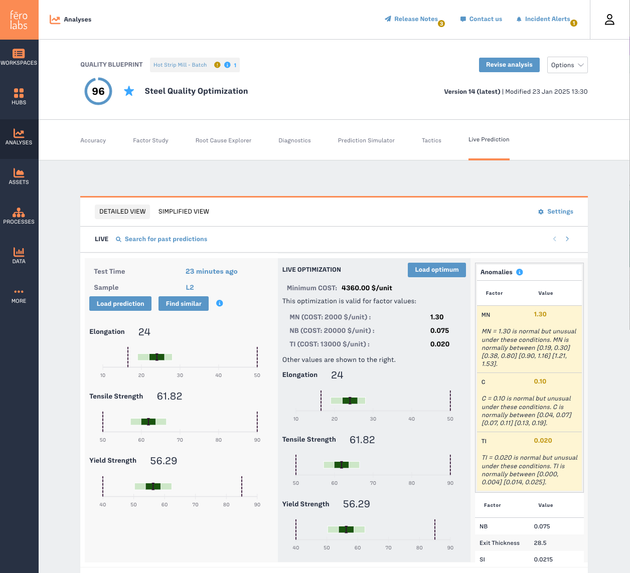

Fero Production

Fero Production supports live operations with real-time alerts, forecasting, and back-testing so teams can intervene earlier and sustain performance as conditions change, with full visibility into why alerts are triggered and how recommendations relate to process behavior.

Problems Fero addresses

Fero software is designed for plants dealing with challenges like:

✅ Slow investigations when process performance drifts

✅ Decisions delayed while waiting for expert input

✅ Trial-and-error changes made directly in production

✅ Improvements that don’t hold when conditions change

✅ Inconsistent decisions across shifts or teams

Most analytics tools and in-house models leave engineers to interpret or justify them. Fero is built to close that gap—so insight leads directly to defensible action.

Fero enables any worker on any shift to make informed expert-level decisions that relieve more of senior engineer's time to focus on strategic initiatives.

What makes Fero different

Fero is not a generic analytics or reporting platform, and it is not a black-box optimization system.

It is built specifically to support explainable and transparent, engineer-led process decision-making in real operating environments. What distinguishes Fero:

- Focuses on process behavior and cause-and-effect, not dashboards

- Encodes how experienced engineers reason about the process, not just correlations

- Makes insight explicit, explainable, and collaborative

- Captures knowledge of senior engineers and makes it accessible to every team and shift

- Supports human decision-making rather than automating it away

This makes Fero difficult to replicate with ad-hoc models or in-house analytics pipelines, which often lack consistency, context, and explainability across use cases.

Profitable Sustainability as an outcome

When process decisions are made faster, more consistently, and with clear reasoning, plants reduce waste, rework, energy use, quality issues, and unplanned downtime. These improvements lower cost and emissions at the same time.

The Fero Labs Profitable Sustainability Platform enables this by improving how processes are understood, explained, and managed day to day—not through reporting or trade-offs, but through better operational decisions.

Explore the platform

Together, these capabilities form the Fero Labs Profitable Sustainability Platform.

Fero Foundation

Prepare data and process context

Fero Diagnostics

Understand why performance changes

Fero Simulator

Explore improvements before deployment

Fero Production

Stay ahead of issues during live operations

Want to see how explainable, expert-level process decisions are supported in practice?

Why Fero is not just an in-house analytics project

Many plants have analytics tools and internal models. These efforts often succeed at producing insights, but struggle to support consistent decision-making over time. Models break when conditions change, assumptions drift, or the people who built them move on. Maintaining context, explainability, and consistency across use cases becomes a full-time effort.

Fero is designed as a system, not a collection of one-off models. It preserves process context, engineering reasoning, and explainability across diagnostics, simulation, and live operations. This consistency across the full decision cycle is what makes the platform difficult and inefficient to replicate with ad-hoc tools or internally maintained analytics projects.

How Fero is used in practice

Fero software is used as part of day-to-day process engineering work, not as a separate analytics exercise. Process engineers use it when performance drifts, when conditions change, and when decisions need to be made with limited time and incomplete information.

In practice, this includes investigating why a process is behaving differently than expected, understanding which variables are most likely driving the change, evaluating potential actions before applying them, and monitoring outcomes to learn from past decisions. The same process knowledge is used throughout, so teams are not re-establishing assumptions or rebuilding context at each step.

Designed for real operating conditions

Steel production processes rarely operate under steady-state conditions. Feed quality changes, equipment performance degrades, constraints shift, and targets evolve. Decisions need to hold up under this variability, not just under ideal assumptions.

Fero is designed to reason about the process as it actually operates, across changing conditions and competing objectives. This allows teams to make decisions that remain valid as conditions evolve, rather than relying on narrow models or static analyses that quickly lose relevance.

Decisions engineers can explain and defend

Process decisions need to be explained to operators, managers, and often reviewed after the fact. Insight that cannot be explained or traced back to process behavior creates risk and slows adoption.

Fero makes the reasoning behind decisions visible. Engineers can see which variables matter, how they interact, and why certain actions are expected to work. This makes decisions easier to align on, review, and defend, especially in high-consequence operating environments.

Scaling expertise without lowering standards

In many plants, experienced process engineers become bottlenecks simply because their knowledge is needed everywhere. This slows decision-making and places ongoing pressure on a small number of people.

Fero does not replace expert judgment. It captures how experienced engineers reason about the process and applies that reasoning consistently. This allows less experienced engineers to act with greater confidence, while senior engineers remain responsible for defining acceptable operating behavior and decision boundaries.

Where Fero fits in the plant

Fero is typically used by process engineering teams in close collaboration with operations. It complements existing control systems, historian infrastructure, and engineering workflows rather than replacing them.

The platform supports decision-making rather than automating it. Ownership of the process, targets, and actions remains with the plant team.

Going deeper into the platform

The following sections describe each part of the platform in more detail: Fero Foundation, Fero Diagnostics, Fero Simulator, and Fero Production.

Why Process Expertise Doesn’t Scale —And What Actually Changes That

How One Global Steel Producer Proved AI Value Quickly — Without Overcomplicating the Pilot

After a Disappointing Digital Rollout: Four Things Steel Mills Do Differently Next Time