Use Case Description

Background

Polyethylene (PE) is one of the most widely-produced plastics, used in a range of applications including packaging, films, bottles, household goods, car parts, pipes and containers. PE manufacturers must continually modify their production processes to adjust to shifting market demands for different PE grades. Such adjustments can often lead to production of off-specification PE leading to waste and avoidable environmental damage.

Problem

Off-spec PE production is both wasteful and costly for plants. This issue primarily arises during transition periods between product grades, in which operational changes are made to meet market demands of specific PE grades.

To mitigate the production of off-spec PE, plant operators will often store and blend off-spec product with PE that meet quality standards.

However, managing the storing and blending of off-spec PE poses substantial challenges, particular when faced with an excess accumulation of off-spec PE and insufficient storage capacity. In such situations, the excess off-spec PE is directly discarded and sent for waste treatment.

This management challenge is exacerbated by the fact that a single PE production plant may produce over ten different product grades, requiring frequent transitions and complicating the task of minimizing off-spec production.

Ensure optimal polyethylene production to produce final product that meets specifications while reducing raw material usage and plastic waste through off-spec production

Identifying the optimal operating conditions during these transition periods is a complex task, especially since the typical interval between measurements of final product quality in a polyethylene plant (such as melt index and ethylene conversion rate) can range from 0.5 to 5 hours.

Between measurements, plant operators must rely on their expertise or follow established operational guidelines to ensure production meets specifications. This is further complicated by the numerous manipulated variables operators can control during production such as reactor temperature, monomer, comonomer, and chain-transfer agent concentrations.

Additionally, they must account for time delays between upstream and downstream production when making these adjustments.

Click here to download the entire Playbook

Fero Labs Solution

Optimizing operational parameters to promote in-spec production while reducing energy consumption can improve process efficiency and reduce the environmental footprint of PE production.

Operators in polyethylene plants can use Fero Labs to predict the final product melt index and density and subsequently run optimizations to minimize the cost of raw material usage.

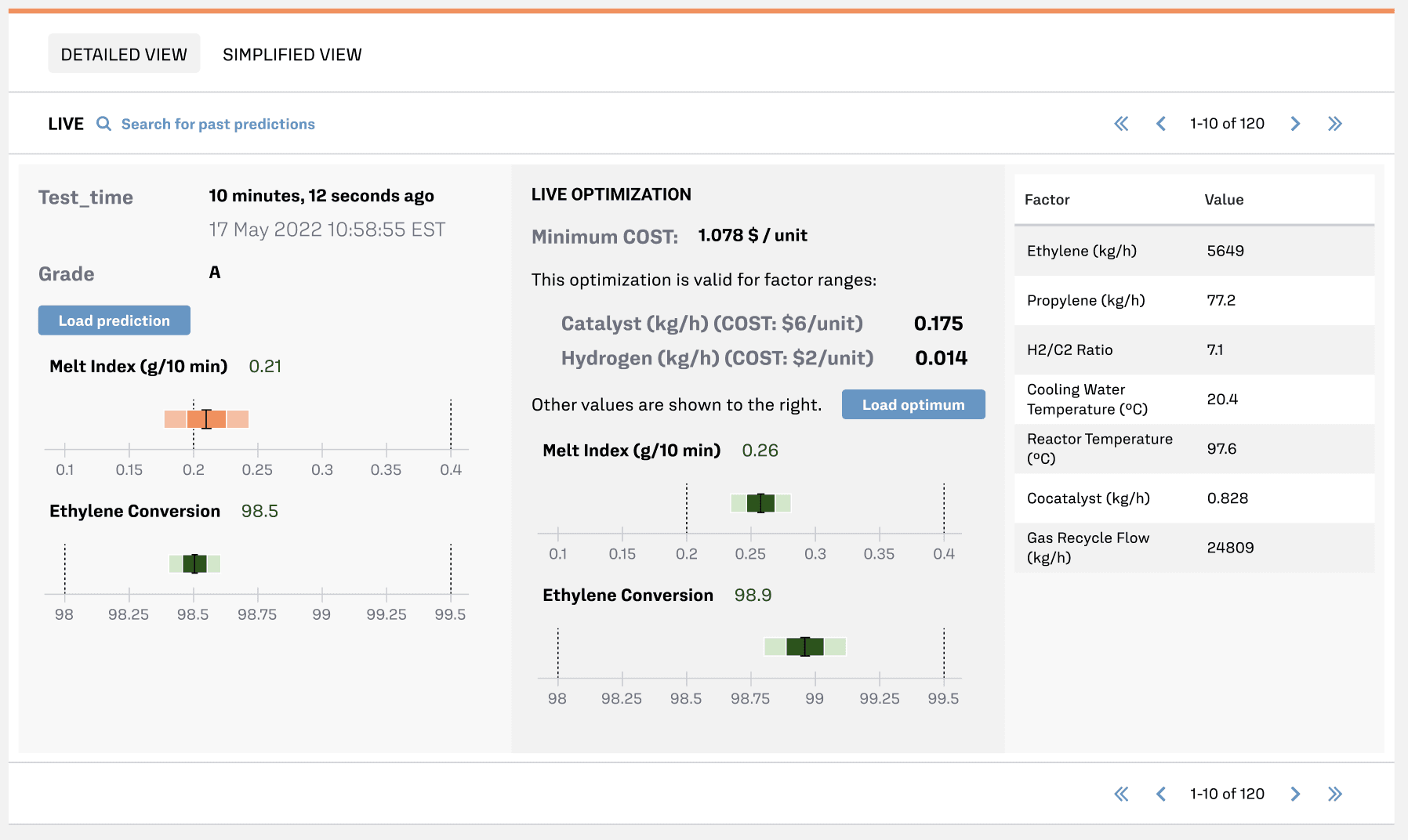

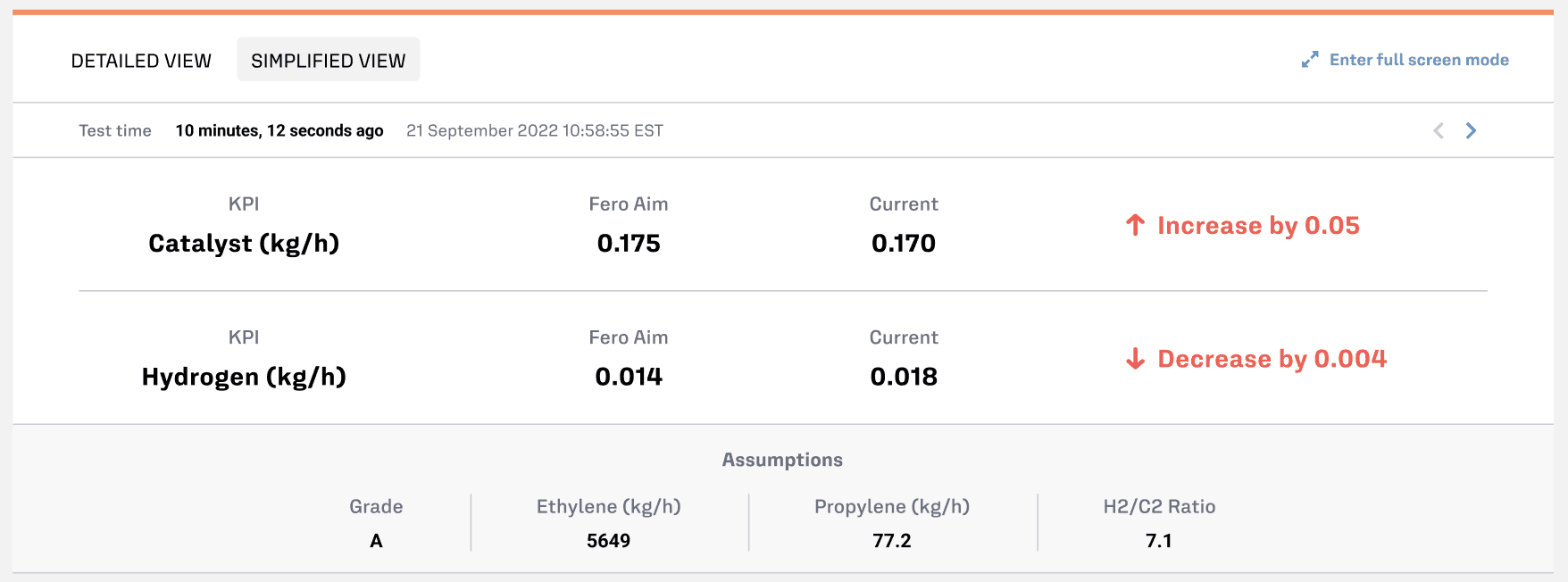

A Live Fero Analysis for this use case presents two screens:

- Detailed View: for production and quality engineers to monitor production and take action at any moment. Fero can be used to perform real-time monitoring of plant performance by predicting the final quality of the polyethylene grade. During the time between lab measurements, the live prediction can also help with early detection of poor-quality product. Steps can then be taken to ensure production is brought back into specification quickly. These changes will minimize total cost of raw material (catalyst, hydrogen) while keeping PE melt index and ethylene conversion within specification for the specific PE grade.

- Simplified View: for operators in control rooms, with critical actionable information clearly presented for a specific PE grade.

Process & Business Outcomes

In-process optimization during product grade transitions

When deployed, Fero considers the varying operational changes made during product grade transitions throughout the production process to make predictions for specific PE grades.

Operators receive real-time, cost-efficient recommendations for adjusting the process parameters to minimize the amount of off-spec production during transition. These recommendations also take into account time lags in measurements made at different stages of production.

With full adoption of Fero Labs software, plant operators can expect to experience up to 50% reduction of off-spec production during grade change transition and up to 30% reduction in transition time.

Reduced plastic waste and minimize Scope 1 and 2 footprint

Monitoring plant performance and predicting final product quality enable plant operators to minimize off-specification production, alleviating the operational challenge of managing excess off-spec PE and mitigating issues related to storage, waste, and environmental concerns.

Minimizing off-spec PE accumulation through real-time optimization supports more sustainable operations, reducing the refinery’s Scope 1 carbon footprint through waste reduction and lowering its Scope 2 carbon footprint by reducing the processing need to reworking an off-spec batch.

Fero Labs Adoption Timeline

Plant teams can collaborate to set up and deploy Fero Labs. Below is a timeline highlighting typical steps. With Fero’s easy-to-use, no-code interface, this can be achieved in a matter of weeks, not months or years.

Data Requirements

Plant teams can collaborate to set up and deploy Fero. Below is a timeline highlighting typical steps. With Fero’s easy-to-use, no-code interface, this can be achieved in a matter of weeks, not months or years.

Activating This Use Case

Consider our Industrial Use Case Playbooks as inspiration and tactical ideas for your team to align on to maximize the efficiencies of your plant.

Each Playbook has a matching Use Case Blueprint which provides more detailed steps to activate each use case within the Fero Labs platform.

If you’re curious to see these in action please book a free feasibility study with our team!

Together, let us continue to push the boundaries of what's possible, driving towards a future where industrial manufacturing is not just efficient and sustainable but truly transformative in its impact on society and the world at large.

Thank you for joining us on this journey, and we look forward to continuing to partner with you in your pursuit of excellence.

Download the entire Polyethylene Production Optimization Playbook to access additional tables and details about this industrial use case.