Use Case Description

Background

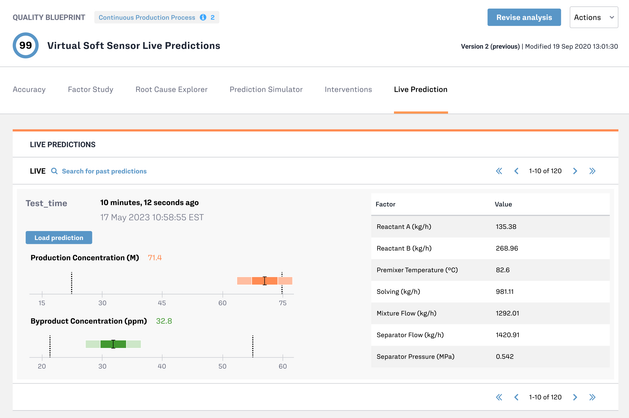

Virtual soft sensors are models designed to predict and monitor “hard-to-measure” quality parameters in real-time, such as laboratory analysis results from samples taken from the process.

Implementing soft sensors enables plant operators to improve efficiency, reduce costs, and enhance product quality by leveraging real-time insights with fewer physical sensors required.

This strategy streamlines operations, reduces maintenance needs, and increases productivity, empowering plant operators to proactively modify process parameters and efficiently identify abnormalities in production.

Problem

In many continuous process production facilities, ensuring the final product consistently meets established industry standards is crucial. Typically, this involves operators manually collecting samples from the final or near-final stage of production and sending them to the lab for analysis. The sampling frequency might range from several hours to daily, with the duration dependent on the particular lab tests performed.

Such intermittent sampling can lead to significant operational delays, particularly during the phases of startup or shutdown or when the process is no longer running in stead-state.

Moreover, the complex relationship between chemical reactions and process variables, including time delays and material flow residence times, presents a significant challenge for plant operators, who must:

Monitor variations in upstream process conditions and proactively take action to ensure these variations do not adversely affect the final product quality.

The prevailing method of course-corrective action when the final product quality falls short of expectation often leads to resource wastage and reduced production efficiency due to extended downtime for inspections, as well as increased environmental and energy costs from frequent stops and restarts of the production cycle.

Fero Labs Solution

A virtual soft-sensor can be configured to predict and monitor the hard-to-measure quality related parameters, such as the outcomes of laboratory analyses of samples collected from the manufacturing process.

This soft-sensor equips plant operators with real-time insights into the production process, helping them to monitor whether the quality related parameters meets industry specifications.

Furthermore, it is instrumental in detecting ongoing quality issues, especially when lab results show that the product fails to meet the quality standards. This is critical in guiding plant operators to make informed decisions on making operational changes or initiating an unplanned shutdown, thus minimizing production losses.

Process & Business Outcomes

Real-time monitoring of production quality

Plant operators can gain real-time insight into production quality without having to wait for lab analysis results. They will also have a direct root-cause insight into how operational changes such as changes in raw material flow rates or temperatures can affect production quality.

In-process optimization based on product quality predictions

Soft sensors can enable plant operators to make adjustments to operational conditions based on product quality predictions. This can increase production throughput by up to 15%. In a market heavily limited by production capacity, this improvement could also translate into a top-line benefit of up to 15%.

Informed decision-making to mitigate unplanned shutdowns

Plant operators can be more confident when deciding to initiate an unplanned shutdown or make an operational change when process abnormalities occur. Similarly, they can be more confident of when they achieve steady-state conditions and production quality within spec during plant startups.

With a full adoption of Fero Labs software, plant operators can expect to experience up to 36% decrease in unplanned production shutdowns and startups.

Reduced lab measurement frequency

A virtual soft sensor can reduce the frequency of lab measurements needed and provide estimates for them at consistent time intervals. This can relieve any laboratory driven process bottlenecks and reduce the total annual lab measurements by as much as 20%, while providing additional visibility into production.

Fero Labs Adoption Timeline

Plant teams can collaborate to set up and deploy Fero Labs. Below is a timeline highlighting typical steps. With Fero’s easy-to-use, no-code interface, this can be achieved in a matter of weeks, not months or years.

Data Requirements

Plant teams can collaborate to set up and deploy Fero. Below is a timeline highlighting typical steps. With Fero’s easy-to-use, no-code interface, this can be achieved in a matter of weeks, not months or years.

Activating This Use Case

Consider our Industrial Use Case Playbooks as inspiration and tactical ideas for your team to align on to maximize the efficiencies of your plant.

Each Playbook has a matching Use Case Blueprint which provides more detailed steps to activate each use case within the Fero Labs platform.

If you’re curious to see these in action please book a free feasibility study with our team!

Together, let us continue to push the boundaries of what's possible, driving towards a future where industrial manufacturing is not just efficient and sustainable but truly transformative in its impact on society and the world at large.

Thank you for joining us on this journey, and we look forward to continuing to partner with you in your pursuit of excellence.

Download the entire Continuous Process Soft Sensor Use Case Playbook to access additional tables and details about this industrial use case.