Playbooks: Industrial Use Cases Using AI

Boost performance

Excel and Six Sigma are go-to process optimization solutions. But these tools can't handle the complexity of today's factory floor. When you’re generating thousands of data points every second, you need a solution that scales. Fero Labs AI is like Six Sigma on steroids.

Fero Labs helps you discover ways to achieve peak performance. By connecting key team members, simulating and optimizing processes, you'll identify and eliminate bottlenecks, reduce cycle times, improve throughput, and retain a playbook of knowledge.

- Predict end product quality to prevent flaws

- Virtually test new formulations and hypothetical scenarios

- Analyze processes to learn the most effective improvements

Reduce costs

By applying Fero Labs to your process, you can identify actions to reduce waste and cost. Fero Lab's white-box contextual machine learning provides a transparent view of the underlying process, allowing you to confidently identify and address inefficiencies 90x faster than traditional methods.

Minimize:

- Total cost

- Energy consumption

- Raw material consumption

- Scrap

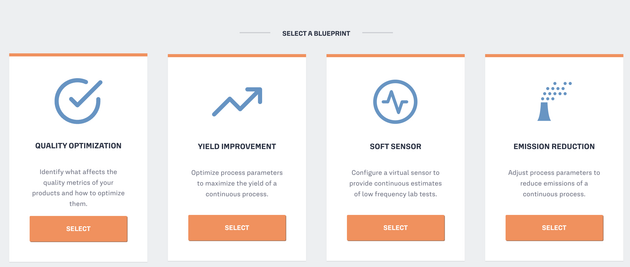

Reduce emissions

Using Fero Labs, you can reduce emissions and costs at the same time. We call this Profitable Sustainability.

By simulating your process and using predictive analytics, you can identify areas of inefficiency and optimize production to reduce waste, maximize raw materials, and create more efficient batch cycle times to save utilities and lower your carbon footprint.

With the powerful lens of white-box ML analyzing your process data, you'll discover actionable ways to target your emissions and costs simultaneously without compromising quality.

- Directly target Scope 1, 2, and 3 emissions

- Jointly reduce emissions and costs

- Track progress with detailed reporting capabilities

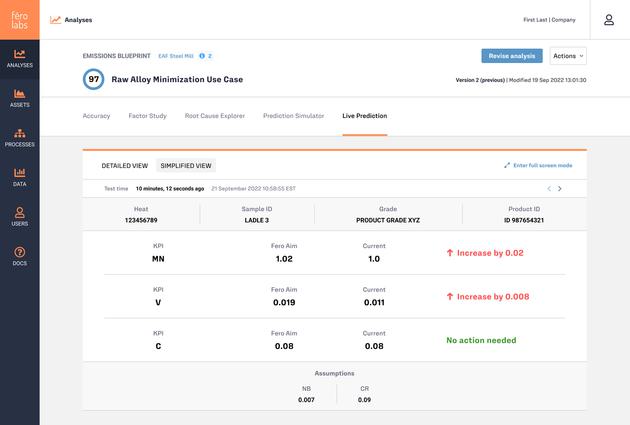

New Release: ExplainIt for Live Predictions!

Fero Labs' Powerful Process Engine Delivers More Value for Your Plant

Anyone who works with data can benefit from adding the Fero Labs Process Engine to their workflow.

- Process engineers can boost the impact of existing studies and workflows by making sure data has proper context before running analyses. They can target use cases that previously would not have been possible, and execute more studies at once thanks to dramatically reduced data clean-up time which saves time and reduces human error.

- Data scientists can enjoy streamlined collaboration with subject matter experts. By leveraging engineers' expertise to perform data clean-up using the Process Engine, they can fast-track the pre-processing and cleaning steps, and focus on modeling, thus improving their productivity, innovation, and speed to insight.

- Executives can make concrete progress towards Industry 4.0 goals by implementing the right technology that helps achieve them. Improved collaboration between plant engineers and central data teams will accelerate productivity, and both EBITDA and carbon emissions will be saved by empowering technical personnel to remove operational bottlenecks.

Learn more about the Fero Labs Process Engine.